My DIY laser project

- Rudy Rawlins

- Posts: 10

- Joined: Tue Jul 02, 2019

- Location: US Virgin Islands

- Country: USA

- Nickname: Rudy

- Laser Machine Make or Type: N/A

- Laser Power: N/A

- Laser Bed Size: N/A

- Home Position: BL

- RDWorks Version: N/A

- Windows Version: 10

I have started sourcing parts for my DIY laser build while I'm working on the design of the frame etc. I am thinking of a 4' by 3' work area and possible a 60watt laser. I'm looking for a quality Chinese laser source that is not terribly expensive.

- Tim Mellor

- Posts: 560

- Joined: Wed May 29, 2019

- Location: Shipwreck Coast, Victoria

- Country: Australia

- Nickname: beanflying

- Laser Machine Make or Type: Vollerun WR3020

- Laser Power: 40W

- Laser Bed Size: 300x200

- Home Position: TR

- RDWorks Version: n/a

- Windows Version: 10

- Accessories: Modded and still Modding some more.

Possibly interested is building a larger format Laser rather than buying one too.

I have had a bit of a look at Cloudray's offerings and they also offer semi kits of linear rails among most of the bits you may need https://cloudray.aliexpress.com/store/1 ... 5cddvokKOG I haven't brought anything from them but their written feedback looks fine.

Bear in mind evilbay and aliexpress are not always paragons of truth or your first place to look to for real information either

4'x3' kit of bits https://www.aliexpress.com/item/3278881 ... 51ccdI1iar

I have had a bit of a look at Cloudray's offerings and they also offer semi kits of linear rails among most of the bits you may need https://cloudray.aliexpress.com/store/1 ... 5cddvokKOG I haven't brought anything from them but their written feedback looks fine.

Bear in mind evilbay and aliexpress are not always paragons of truth or your first place to look to for real information either

4'x3' kit of bits https://www.aliexpress.com/item/3278881 ... 51ccdI1iar

- Rudy Rawlins

- Posts: 10

- Joined: Tue Jul 02, 2019

- Location: US Virgin Islands

- Country: USA

- Nickname: Rudy

- Laser Machine Make or Type: N/A

- Laser Power: N/A

- Laser Bed Size: N/A

- Home Position: BL

- RDWorks Version: N/A

- Windows Version: 10

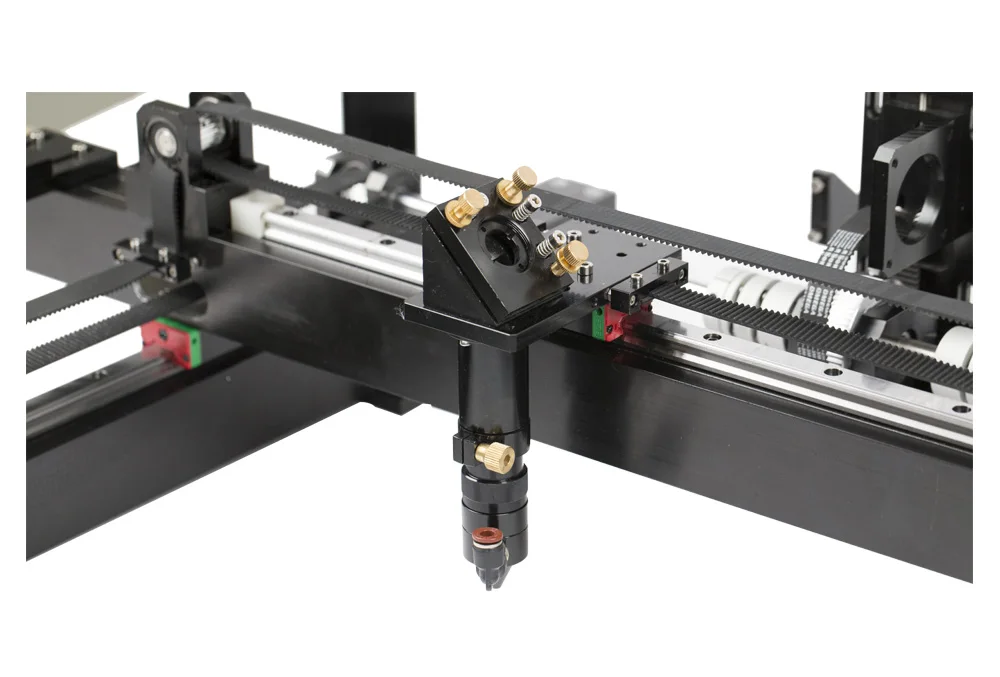

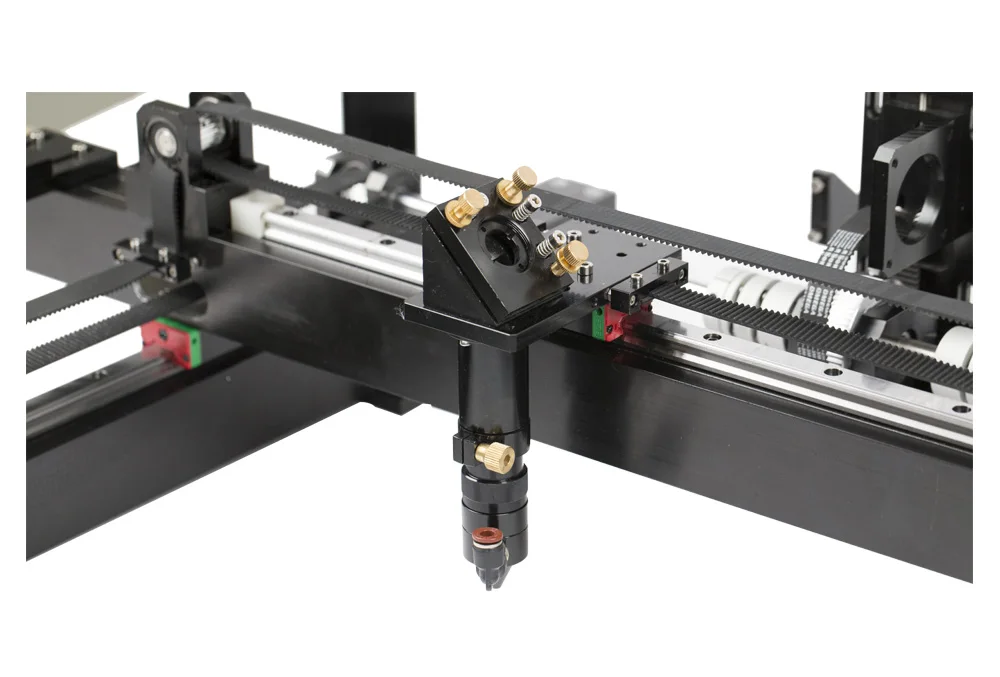

I just bought the cloudray E Series head and mirror kit from Aliexpress yesterday. I would like to make the printer independent and contemplating using a beaglebone black to control the machine. It all depend on what I can find. I will use 2040 extrusion for the structure.

- Tim Mellor

- Posts: 560

- Joined: Wed May 29, 2019

- Location: Shipwreck Coast, Victoria

- Country: Australia

- Nickname: beanflying

- Laser Machine Make or Type: Vollerun WR3020

- Laser Power: 40W

- Laser Bed Size: 300x200

- Home Position: TR

- RDWorks Version: n/a

- Windows Version: 10

- Accessories: Modded and still Modding some more.

Keep an eye on what I am up to with electronics with my current little toy with a Smoothieboard/Mini ITX Atom. No way I would engage in the pain of something non windoze for a CNC machine front end unless you have extreme dedication to the cause

- Rudy Rawlins

- Posts: 10

- Joined: Tue Jul 02, 2019

- Location: US Virgin Islands

- Country: USA

- Nickname: Rudy

- Laser Machine Make or Type: N/A

- Laser Power: N/A

- Laser Bed Size: N/A

- Home Position: BL

- RDWorks Version: N/A

- Windows Version: 10

My original intention is to go with a 60w tube. But to increase it to an 80 or a 100 watt later. So I'm assuming I can run a 60w tube on a 100w power supply and would only have to change the tube later. So am I right or am I wrong?

- Rudy Rawlins

- Posts: 10

- Joined: Tue Jul 02, 2019

- Location: US Virgin Islands

- Country: USA

- Nickname: Rudy

- Laser Machine Make or Type: N/A

- Laser Power: N/A

- Laser Bed Size: N/A

- Home Position: BL

- RDWorks Version: N/A

- Windows Version: 10

I'm looking for an arduino circuit with sketch that will keep the laser turned off until it senses a pulse from a hall effect switch at a specific rpm.

- Tim Mellor

- Posts: 560

- Joined: Wed May 29, 2019

- Location: Shipwreck Coast, Victoria

- Country: Australia

- Nickname: beanflying

- Laser Machine Make or Type: Vollerun WR3020

- Laser Power: 40W

- Laser Bed Size: 300x200

- Home Position: TR

- RDWorks Version: n/a

- Windows Version: 10

- Accessories: Modded and still Modding some more.

Let us know what you are sensing? I am assuming flow based on motor rotation? If that is the case consider adding a flowmeter instead as pumps fail while motors can keep going. Something like this Evilbay Link

This while not a design is a good place to start with a google search of rpm relay arduino site:forum.arduino.cc Plenty of ideas and code snippets.

Relay rather than solid state switch because they are simple but a mosfet driven by the Arduino is fairly simple too. Are you wanting to keep the Laser power supply itself off or just interrupt the signal from your controller? The circuit below as an example of driving a relay with a Mosfet could simply have the 12V coil of a relay where it shows solenoid (basically the same thing) to then handle the mains voltage to the PS. There is one omission that is good practice is a diode across the coil to reduce spikes when switching.

Just a start point for you.

This while not a design is a good place to start with a google search of rpm relay arduino site:forum.arduino.cc Plenty of ideas and code snippets.

Relay rather than solid state switch because they are simple but a mosfet driven by the Arduino is fairly simple too. Are you wanting to keep the Laser power supply itself off or just interrupt the signal from your controller? The circuit below as an example of driving a relay with a Mosfet could simply have the 12V coil of a relay where it shows solenoid (basically the same thing) to then handle the mains voltage to the PS. There is one omission that is good practice is a diode across the coil to reduce spikes when switching.

Just a start point for you.

- Rudy Rawlins

- Posts: 10

- Joined: Tue Jul 02, 2019

- Location: US Virgin Islands

- Country: USA

- Nickname: Rudy

- Laser Machine Make or Type: N/A

- Laser Power: N/A

- Laser Bed Size: N/A

- Home Position: BL

- RDWorks Version: N/A

- Windows Version: 10

This is a prototype of a water flow sensor I'm putting together. It will have a hall effect magnetic sensor attached to it and the paddle will have two 2mm magnets on opposite ends embedded in it. I want to be able to monitor the flow of water while also be able to have the laser power turned off until the water flow level reaches a specific threshold. If the water flow drops more than a certain percentage the unit kills the power. This of course is switched with a relay. Using a micro controller open options for additional control and monitoring.

You do not have the required permissions to view the files attached to this post.

- Tim Mellor

- Posts: 560

- Joined: Wed May 29, 2019

- Location: Shipwreck Coast, Victoria

- Country: Australia

- Nickname: beanflying

- Laser Machine Make or Type: Vollerun WR3020

- Laser Power: 40W

- Laser Bed Size: 300x200

- Home Position: TR

- RDWorks Version: n/a

- Windows Version: 10

- Accessories: Modded and still Modding some more.

Makes sense all you need to do is count pulses from the Hall effect over a block of time then if pulse/time is over or under X allow or stop using a circuit similar to what is above.

Off topic a little your Printer looks to be under extruding. Check your extruder is close to the correct length by marking some filiment and or crank up the multiplier a touch.

Off topic a little your Printer looks to be under extruding. Check your extruder is close to the correct length by marking some filiment and or crank up the multiplier a touch.

- Rudy Rawlins

- Posts: 10

- Joined: Tue Jul 02, 2019

- Location: US Virgin Islands

- Country: USA

- Nickname: Rudy

- Laser Machine Make or Type: N/A

- Laser Power: N/A

- Laser Bed Size: N/A

- Home Position: BL

- RDWorks Version: N/A

- Windows Version: 10

The head and the heat break need replacing they're 2 yrs old. Just a bit lazy to get around to it.